User interviews《SEKISUI CHEMICAL CO., LTD.》Accelerating the industrialization of cell manufacturing with the industry's first* scaffold material made of chemically synthesized polymer.

"Time-lapse imaging captures cell activities, leading us towards an appropriate polymer design."

* As of July 9, 2021, based on SEKISUI CHEMICAL CO., LTD. research.

SEKISUI CHEMICAL CO., LTD.

Main Business fields

Manufacture, construction, and sales of unit housing; housing-related services such as renovations; manufacture and sales of plastic products for various industries including construction, civil engineering, vehicles, and electronics; and manufacture and sales of in vitro diagnostic agents and testing devices

Interviewee

Advanced Technology Institute, R&D Center CorporateSatoshi Haneda Ph.D.

Adopted equipment/systems

*This product has been discontinued. If you have any questions about cell cultures, assays, or products, please contact us using the contact form.

SEKISUI CHEMICAL Group contributes to improving the lives of the people around the world and the Earth's environment through creating innovations while continuing to open up new frontiers in ‘residential and social infrastructure creation’ and ‘chemical solutions’. In the life science field, the company has succeeded in developing an innovative plastic scaffold material made of chemically synthesized polymer and realized a culture vessel design that enables stable cell culture. Nikon's BioStudio-T cell observation system contributed to accurate judgment for the direction of polymer development through acquisition of detailed information about cell adhesion and the proliferation process. The system helped lead to this innovation, which could significantly advance the industrialization of regenerative medicine. We spoke with Haneda, who led the project, about how the BioStudio-Thelped solve development challenges.

Contents

Show- SEKISUI CHEMICAL CO., LTD. innovations

- Challenges prior to introduction

- Effects of introduction

- Future expectations

SEKISUI CHEMICAL CO., LTD. innovations

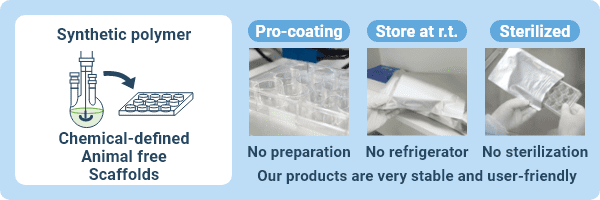

Scaffold material that creates an environment where cells can easily proliferate

SEKISUI CHEMICAL Co. Ltd. (hereinafter SEKISUI CHEMICAL) has developed a scaffold material made of chemically synthesized polymer for cell culture and started to provide sample products. You are the first in the industry to develop such a product.

Yes. SEKISUI CHEMICAL was initially established in 1947 with the aim of creating a comprehensive plastics business. Since then, we have taken advantage of plastic design and processing/molding technologies to provide diverse products essential for various industries, such as interlayer films for the laminated glass used in automobile windshields and adhesives for LCDs, with the aim of contributing to solutions for various social issues.

Today, industries that utilize cells, such as regenerative medicine and gene therapy, are emerging worldwide. So, we thought we could employ the technologies that we have been nurturing to provide scaffold materials that fill in the existing gap, improving productivity, quality, and storage stability while helping to promote the industrialization of cell culture – which led to this development. There weren’t any known scaffold material products that would allow iPS or ES cells to adhere and proliferate and that could be handled in the same way as plastic products. I think we were able to propose a fresh new concept.

Could you tell us what the scaffold materials are and their role in cell culture processes?

Scaffold materials act as adhesives that allow cells to colonize the surface of culture vessels, such as plastic or glass dishes and plates. Cells adhere to each other via proteins. If this in vivo environment is not sufficiently reproduced, cells cannot maintain their functions, leading to cell degeneration and death. So, the surface of a vessel is coated with scaffold material to produce an environment similar to in vivo that cells can easily colonize. This is the role of scaffold material. We also lay flooring material such as carpet on the floors of our homes to make our lives more comfortable, don't we? That image is probably closely analogous to the role of these materials.

Developing the industry's first scaffold material made of chemically synthesized polymer

So, it's an innovation that the scaffold material is made of chemically synthesized polymer?

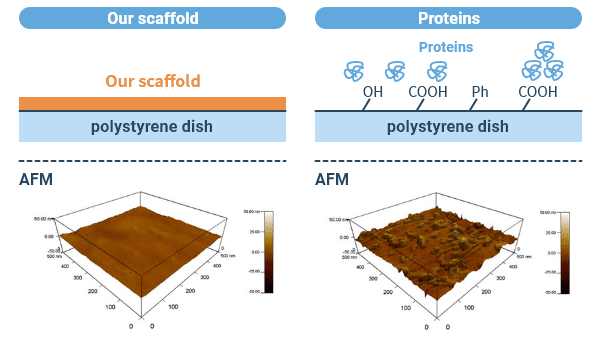

That’s correct. Until now, water-soluble proteins extracted from animal cells have mainly been used for conventional scaffold materials. However, culture vessels are generally made of plastic, which does not readily adsorb water-soluble substances. Also, although the intention is to homogenously spread the scaffold proteins, you may not be able to apply them evenly, depending on the vessel material or skills of the culture worker. When you observe the vessel surface with an electron microscope, it's not smooth. In addition, even after application, proteins elute into the medium because of their water-soluble properties or become denatured by heat, leading to an uneven distribution of scaffold material.

スクロールできます

| SEKISUI-developed scaffold | Conventional product | |||

|---|---|---|---|---|

| Chemically synthesized polymer (water-insoluble) |

Protein (water-soluble) |

Peptide (water-soluble) |

||

| Cell culture capability | iPSC adhesion | Good | Good | Good |

| Safety | Elution | High: Hydrophobic polymer | Low: Water-soluble | Low: Water-soluble |

| Animal-free | Yes: Chemical-defined | No: Animal content | Yes/No | |

| Handling properties | Evenness | High: Coated evenly by machine | Low: Adsorbed unevenly | Low: Adsorbed unevenly |

| Scalability | High: Uniform surface | Low: Free adsorption | Low: Free adsorption | |

| Stability | High: Room-temp. stable | Low: Thermo-sensitive | High/Low | |

Synthetic polymer scaffold material that is easy to use and can be applied to various culture systems.

Challenges prior to introduction

Images of the effect of the culture surface on cell culture.

Filling in the gap left by protein-derived scaffold materials

So, the environment that cells colonize cannot be uniform.

That's right. This fact tends to be overlooked at the level of culture in a small vessel in a laboratory. However, if a scaffold material is not smooth, cell culture also becomes uneven, and the culture quality lacks stability. At the stage of constant production in large containers at an industrial level, it becomes a matter of quality control. So, we thought that if we could utilize our strength in polymer design technology to provide an even surface for large-scale culture, we could contribute to the industrialization process.

It's very innovative that you have resolved the weakness of water-soluble proteins and are supporting the progress of industrialization.

Thank you. The ‘synthetic polymer scaffold material’ that we have developed possesses two characteristics that are difficult to achieve with protein-derived scaffolds: insolubility in water and heat stability. Both characteristics are realized while maintaining a high degree of adhesiveness, due to its optimum design for cells. We are planning to provide culture vessels coated with the ‘synthetic polymer scaffold material’ as a product, which will support stable production of cells with less troublesome work.

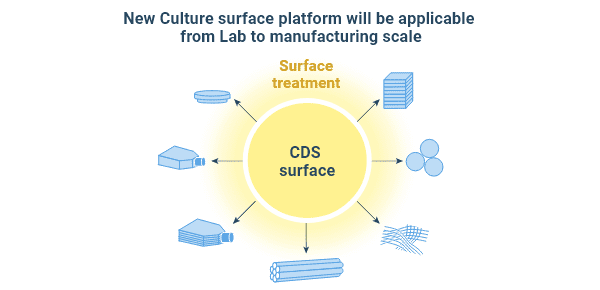

In addition, this material can be used as a scaffold ink for evenly coating a variety of materials and shapes. So, we also expect to help develop cell culture devices featuring factory automation that are highly automated and will work as closed systems.

Time-lapse imaging supports unprecedented challenges

During the development stage, how did you evaluate the suitability of the synthesized polymer scaffold material for the cells?

We used cell adhesiveness and proliferation as indicators. Cells that fail to adhere become crushed, stretched, or deformed. Therefore, during the earlier stages of development, we evaluated adhesiveness on a 10-point scale by visually observing cell shape under a microscope. To assess proliferation, we stained cells removed from culture and counted them with a measurement instrument.

Could you tell us about the difficulties and challenges during the development process?

Because this was a completely new challenge, we couldn't apply some of the usual development approaches that make minor changes to known materials or methods. There were too many hypotheses about material design and indicators, so we couldn't easily discover which one to rely on. It seemed that the most efficient way to move forward was to make a huge number of samples, then evaluate them to narrow them down. In particular, some of the more troublesome cases occured when cells adhered but didn't proliferate, or proliferated but didn't form well. Unexpectedly, these cases were often observed, and it was hard to determine what was causing them. One day, at an exhibition, I saw Nikon’s BioStudio-T by chance. Even at first sight, I thought, ‘This is surely going to be helpful!’ Once we actually introduced it, we achieved exactly the intended results.

We have heard that you purchased multiple units. How did the BioStudio-T help you?

When we observed cells with the time-lapse imaging function, we found that the micro-scale ‘activities’ of cells were key for developing indicators.

Effects of introduction

BioStudio-T installed in an incubator.

The ‘activities’ of cells appear when using time-lapse imaging

Micro ‘activities’ of cells? Did the time-lapse imaging function of the BioStudio-T capture their movements?

Yes. The BioStudio-T worked very well. Using time-lapse imaging, we gained detailed information about cell adhesion and the proliferation process, which helped us accurately determine the development direction.

Could you be more specific?

Although I said previously that we determined the adhesiveness based on the cell shapes, the shapes we evaluated were just a snapshot capturing only one moment. Regarding the micro-scale phenomenon, we found that cells were moving around or migrating more than expected when we checked the time-lapse images. Cells were moving like inchworms. Their way of movement became an indicator.

So, at the micro scale, cells can move quite well.

That's right. Cells find it difficult to live alone, so when they move and mingle with other cells, they are more secure and proliferate. The time-lapse imaging of BioStudio-T revealed these phenomena. Therefore, we decided to use ‘cells show similar activities to those on a protein-derived scaffold material’ as an evaluation indicator and narrowed down the selection of chemically synthesized polymer.

The observation results of BioStudio-T linked to indicator development

How often did you take images?

When we first started doing time-lapse observations, we shot every 10 to 20 minutes for a week. And during numerous data analyses, we found that the most important period was between one and two hours from seeding. Some cells that fail to adhere could not stimulate signal pathways for survival and become deteriorated. Sometimes, cells tremble seemingly in a painful way and then die while scattering their organelles, which are considered to be the internal organs of cells. The seeding process is generally known to impose a considerable burden on cells. When you see this with your own eyes, you will realize that seeding is a rather traumatic event that radically affects the cellular environment and survival. When developing materials for proliferating cells, it is very important to stay closely attuned to the life events of cells.

I see, so providing a comfortable place for cells is really important. By the way, what is your impression of the image quality provided by the BioStudio-T?

Because I’m only familiar with Nikon's device, I can't really compare it with other brands. However, using the BioStudio-T, we were able to successfully observe the cell ‘feet’, observe cell boundary length and aspect ratio (ratio of vertical and horizontal length), and count the number of cell protrusions exactly; that's how we could link the observation results to indicator development.

Thank you for your feedback.

Another advantage: the plate does not shift or shake easily

Another big advantage of the BioStudio-T is that the culture vessel does not shake. There is no need to move vessels because the lens moves under the plate. In addition, the vibration of the lens drive motor is not transmitted to the plate, so the vessels don’t vibrate. If the BioStudio-T wasn't a device that provided all this extra consideration, we would not have been able to acquire sufficiently accurate information on cell adhesion during a sensitive period – right after seeding, when whether the cells adhere or not is determined. It's very helpful that observation is not affected by external noise. Also, when I removed a plate and exchanged the medium, the micro-scale position control function of the system minimized displacement due to vessel removal or mechanical error. This was also extremely beneficial.

Thank you very much. What did you feel when you observed the cell behavior?

Well, at that time, I was repeatedly observing the life events of the cells seeded on a scaffold material where they were proliferating while migrating. Cells were proliferating while relatively still or vigorously moving, depending on the design of the chemical synthetic polymer. So, I was developing the material while immersing myself in the fascinating thought that I was actually controlling the fate of the cells.

Future expectations

Aiming to contribute to the advancement of industrialization of cell culture

Could you tell us about the future development of this ‘synthetic polymer scaffold material’ ?

Culture vessels for cell culture have previously sometimes been uneven regarding their surface properties, even within the same batch, and there is also unevenness in protein-derived scaffold materials. These variations pose a significant problem in terms of quality control and yield when cell culture is industrialized. The ‘synthetic polymer scaffold material’ we have recently developed ensures the same level of adhesiveness across the surface and can be modified for various culture surface shapes. So, it provides the ideal vessel coating for cell culture. In this sense, we believe that it will be a key material for producing cells for use in regenerative medicine.

Applications of synthetic polymer scaffold material

So this ‘synthetic polymer scaffold material’ is a product designed with the industrialization of cell culture in mind, isn't it?

Yes. This material is modified by protein-based ligands so that it can be used with a variety of cells. The properties of cells vary greatly depending on cell type. For example, cardiomyocytes prefer a hydrophobic environment, while MSCs (mesenchymal stem cells)favor a hydrophilic environment. Our ‘synthetic polymer scaffold material’ can be custom-tuned according to cell preferences by polymer design including ligands. This cannot be achieved with protein-derived scaffold materials. Currently, various safety tests are underway, and we are in the process of perfecting the product so that it can be securely used in the cell manufacturing field. We are also proceeding with collaborative research with clinical doctors. We would like to promote activities to listen to the voices of those in the development field of the therapeutic pipeline in the future.

Thank you. If launched, I expect it will be a driving force that will greatly promote the industrialization of cell manufacturing.

*All information is current as of the time of the interviews.Related cases

Nikon will contribute to solving your cell culture issues with its image analysis

techniques and know-how on cell quality evaluation.

Click hereInquiry Form